The 2 ¾ h.p. overhead valve T.T. pattern, which will be placed on the market as a standard production.

The connecting rod, flywheel and cam

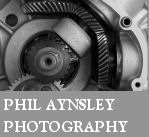

The skew gear magneto drive with the cover removed.

A feature of the new 4¼ h.p. Blackburne engine is the increased size of radiating fins round the valve ports.

The Motor Cycle NOVEMBER 3rd, 1921.

Four Singles and Four Twins to be offered Next Year.

BLACKBURNE engines for 1922 will include at least two completely new models. These are the 4 ¼ h.p. and the 2 ¾ h.p. T.T. engines. The larger of these has a bore and stroke of 85 X 97 mm. (548 c.c), and like all the latest pattern Blackburne engines the finish has been much improved, the crank case being sand-blasted, and the magneto and timing gear cases polished.

The chief improvements in this pattern lie in the provision of larger and deeper radiating fins, especially round the valve ports, a roller bearing big end, and a new cam and exhaust rocker. The new cam is so designed that it first lifts the valve gradually, then opens it rapidly, keeps it open a longer period than the old cam, and then allows it to close quickly; consequently, on account of the overlap, greater efficiency is obtained. The crankshaft is of the built-up variety, while the crank webs are steel stampings.

It is interesting to be able to record that the T.T. engine, with overhead valves, which came near to winning the Junior T.T., is to be placed on the market for the coming year. Since the classic event, however, it has undergone several modifications, one of these being the placing ot the sprocket outside the flywheel, thus reducing the overhang and bringing the flywheel nearer the crank case. This arrangement not only brings the sprocket l ½ in. closer to the crank case, but considerably facilitates the enclosure of the chains. The new flywheel is lighter than the old pattern, has the inside of the mainshaft hole hollowed out, and the main bearing boss slightly chamfered.

Advance Details of 1922 Models.

The split hardened steel bushes for the o.h.v. rockers are mounted on supports screwed into the detachable head and secured by a lock-nut. In the case of the latest models, the main adjustment is effected by means of the usual adjustable tappet as found on side valve engines ; but further adjustment can be obtained by means of the supports, which may be screwed or unscrewed, and then held by the lock-nut. No adjustment is now provided on the end of the rocker arm, which strikes the valve stem ; but, following car practice, a cam pad is provided. The timing gear is the same as the standard 2 ¾ h.p. engine.

Great care is taken to prevent distortion in the Blackburne cylinders and other parts ; and all castings, such as cylinders, pistons, and cylinder heads are normalised - that is to say. they are first rough machined, then put in an oven, and heated to 800° C. for two hours, and allowed to cool ; the process is then repeated, and the cylinders are finally finished off.

The piston is of standard design, but is very light. The full range of 1922 engines: consists of the following : The 2 ¾ h.p. standard model; the 2 ¾ h.p. T.T. pattern, as described above; the standard. 4 h.p. and the 4 ¼ h.p. new type with roller big-end, previously referred to; the 5-6. h.p. twin, 71x88 mm., 695 c.c. ;the 8 h.p., 85x88 mm., 998 c.c. ; and the 10 h.p., air or water-cooled, 85x97 mm., 1,098 c.c. All Blackburne twin-cylinder engines have the cylinders set at 60°, and all may be fitted with the spiral drive magneto, and are suitable for motor cycles or cycle cars. Naturally, the well-known features of these engines - the detachable head and outside flywheel - are retained.

Source: The Motor Cycle

A new long stroke Blackburne twin with overhead valves, with a bore and stroke of 71 x

97 mm. = 768 c.c.

(R.) The cylinder heads have been entirely redesigned and the makers claim 80 m.p.h.

has been attained by this model.

Two New Medium-size Blackburne Twins with Overhead Valves.

THERE is no doubt that it is a modern tendency to favour the small high-efficiency type of engine. It is generally speaking more easy to get the utmost efficiency out of a small engine than out of one of larger capacity. The small engine, moreover, is necessarily lighter, more economical and, if properly designed, can be induced to give practically the same results as one of larger size.

Messrs. Burney & Blackburne have certainly done wisely in introducing a new 5-6 h.p. overhead valve engine suitable for sports models and fast sidecar outfits. The engine is composed of two 350 c.c. cylinders, and may be had in two patterns : short stroke, 71x88 mm., 626 c.c., or long stroke, 71x97 mm., 768 c.c.

In general appearance it is decidedly attractive. The cylinders are set at 60°, and the arrangement of the valve gear is almost identical with that of the well-known 350 c.c. T.T. engine. The model under consideration can be supplied either with cast iron or aluminium pistons and with ordinary or special cams, with which, its manufacturers claim, it is possible to attain over 80 m.p.h. The flywheel is light and very close to the crank-case, the chain sprocket being carried on the outside. Notwithstanding, the main bearing dimensions, 2 15⁄16in., have not been interfered with.

The timing gear is of simple design, there being one cam wheel for each cylinder and a single cam for each inlet and exhaust.

On the cylinder head the fins are deep and numerous, while the exhaust ports are of ample dimensions.

An engine which has not been previously dealt with is the new 8 h.p., which since reference was last made to it in these. pages has undergone one of two alterations. Chief among these is the fitting of an entirely new cylinder head with greatly increased radiating surface, deeper fins being fitted, while the design of the ports has been considerably improved.

The Motor Cycle, May 18th, 1922. Page 637